Dyna Cloud Grey Sanded Floor Grout 25lbs GROU-31

DESCRIPTION

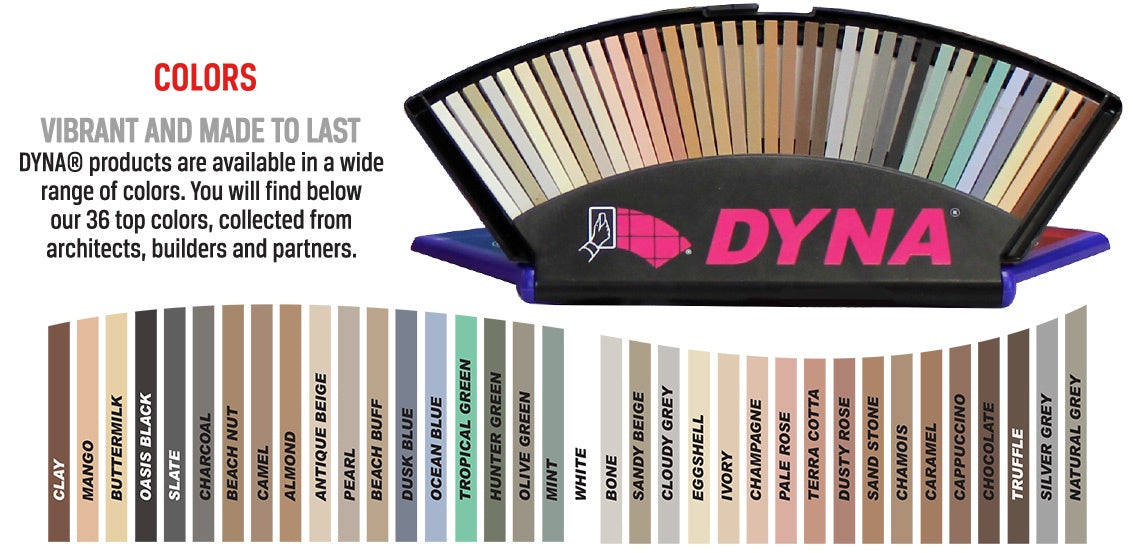

A premium performance pre-mixed (sanded) polymer-modified Portland cement tile grout that only requires the addition of water for mixing. DYNA® DYNACOLOR 2000 is available in a broad range of colors.

USES

- To be used to grout interior and exterior wall tile surfaces. For grouting countertops, swimming pools, and ceiling installations.

- For grouting natural and dimensional stone, granite, un-polished marble, stone agglomerates, slate, ceramic, porcelain, pavers and clay tiles when the joints are between 3 mm (1/8”) and 15 mm (5/8”).

- For grouting tiles set over exterior grade plywood.

- For grouting impervious mosaics.

ADVANTAGES

- EASY TO HANDLE

Plastic, workable, and glides on. One-part system, no need to add liquid latex admixture.

2. PREMIUM PERFORMANCE

High compressive strength, abrasion resistance and flexibility. Impact and vibration resistant. Freeze / thaw resistant.

3. VERSATILE

Ideal for residential, commercial and industrial applications. For exterior and interior.

STANDARDS

Exceeds ANSI A118.6 Requirements.

LIMITATIONS

- Do not use to grout joints that are greater than 3 mm (1/8”) wide.

2. Do not use when a high chemical, impact and stain resistant grout is required. Do

not use in a heavy industrial installation. Use DYNA® DYNAPOXY 6000 in these installations.

3. Do not use for grouting non-vitreous glazed wall tiles or polished marble installations. Use DYNA® DYNACOLOR 1000 (unsanded) polymer-modified Portland cement grout.

4. Do not use at temperatures below 10°C (50°F) or above 38°C (100°F).

DIRECTIONS

A. SURFACE PREPARATION

1. Ensure that the tiles are firmly set and the mortar or adhesive is completely dry.

2. Remove all spacers, pegs, ropes or strings.

3. Ensure that the grout joints are clean and free or dust, dirt, foreign matter or water. Clean the surface or the tile or stone surface thoroughly to remove any dust, dirt, grime or any other contaminants which may discolor the grout. Use DYNA brand of cleaners.

4. Remove excess and residual mortar or adhesive from the joints so that 2/3 of the depth of the tile is available for grouting.

B. MIXING

- Before mixing the grout, dry blend the grout in order to avoid color variations in the finished grout. If two or more packages of grout are used dry blend all the contents together.

- Use a clean mixing vessel and a slow speed mixer (approximately 150 R.P.M.).

- Use cool clean water for mixing. Do not mix grout with other additives. Pour the required amount of water first into the mixing vessel and gradually add in the grout powder while mixing. To avoid shade variations of the finished grout always add the grout powder to the water and be consistent in the mixing process. Ensure that you use a consistent amount of water from batch to batch. As a guideline mix the grout powder to water in the following proportions:

Mix the Grout Powder to Water In the Following Proportions

| Water | Grouting Compound |

|---|---|

| 750 ml (25 US oz.) | 2.2 kg (5 lbs.) |

| 1.88 L (50 US oz.) | 11.3 kg (10 lbs.) |

| 3.78 L (120 US oz.) | 22.7 kg (50 lbs.) |

4. Avoid prolonged mixing which will shorten pot life and cause air entrapment.

5 Allow the grout to slake for about 10 minutes.

6. After the grout has slaked remix without adding anymore grout powder or liquid.

7. Some stiffening of the grout may occur before all the grout is used (approximately 1 hour). If this occurs merely remix the grout but do not add any more liquid.

8. Wash your mixing tools with water immediately after mixing.

C. APPLICATION

1. To assist in the wetting and spreading of the grout, slightly moisten the tile or stone surface with a damp sponge but do not leave excess moisture. Do not permit the un-grouted joints to flood with excess water.

2. Press the grout into the joints with a rigid rubber float.

3. Ensure that all the joints are well compacted and free of gaps and voids.

4. The grout surface should be flush with the tile edge. Remove excess grout from the tile surface, moving the float diagonally to the joints while the grout is still fresh.

5. Ensure that you use consistent application procedures throughout the entire installation surface in order to produce consistent results.

D. EXPANSION AND CONTROL JOINTS

1. Provide expansion and control joints where specified.

2. Do not cover, bridge or fill any expansion joints with grouting compound.

3. Cut tiles on both sides along the edges of the expansion joints.

4. Insert the specified compressible bead and sealant to caulk the expansion and control joint.

5. Follow ANSI AN 3.8, “Requirements for Expansion Joints“.

F. CLEANING

1. Permit the grout to firm up in the joints for about 15 to 30 minutes to prevent damage to the grout surface. If high humidity and low temperatures are present more time will be required.

2. Use two buckets of clean water, the first for rinsing the grout residue from the cleaning towel and the second for moistening the cleaning towel in clean water.

3. Wet a towel and rinse all excess water. Pull with gentle motion the flat damp towel diagonally across the surface of the tiles or stone, to remove the remaining grout residue and to smooth the surface of the grout joints. Perform this procedure by repeatedly washing and wringing out the towel. Do not use a sponge. Never use excess force as this may scratch the tile surface or damage the grout joints.

4. Change the water in the buckets frequently to prevent the development of a haze or film on the tile or stone surface.

5. Do not use excess water as this will cause efflorescence, discoloration, inconsistency, and soft or powdery grout joints.

6. To remove efflorescence, rebuff the tile and grout surface one to two hours afterward with a clean, dry, and lint free cloth to remove any excess surface water or grout residue.

7. Clean hands and tools with clean water.

8. After the grout has initially cured, to facilitate grout film removal use a recommended brand of DYNA grout film remover.

G. PROTECTION AND CARE

- Provide for dry, heated storage on site and deliver materials at least 24 hours before tile work begins.

- Protect tile-work from freezing and complete water immersion for at least 28 days after the completion of the work performed.

- Do not walk on the tiles for at least 48 hours after the installation. Plywood stepping boards may be used after 24 hours when it is unavoidable to occasionally step on the floor. Do not permit heavy traffic to pass on the tiles for at least 7 days after the installation. Protect walls from impact, heavy hammering and vibration on opposite and adjacent walls for at least 14 days after installation.

- When working in cold temperatures or high humidity protect the tile-work for an extended period of time to permit the grout to adequately cure before you permit traffic to walk on the tiles.

- To properly care for your grouting joints use a recommended brand of DYNA cleaner.

- To ensure increased protection and life of your grouting joints use a recommended brand of DYNA sealer.